This spring I was infected with a case of helium hand, and voluneered to make the queens gift for my embroider's guild. The queens gift is given by the keepers of Athena's Thimble to each queen around the time she steps down, as a tribute to her and her service. I had a glorious and terrible idea for something the at the time princess might like, and therefore, under the influence of caffeine and terrible ideas, raised my hand.

This spring I was infected with a case of helium hand, and voluneered to make the queens gift for my embroider's guild. The queens gift is given by the keepers of Athena's Thimble to each queen around the time she steps down, as a tribute to her and her service. I had a glorious and terrible idea for something the at the time princess might like, and therefore, under the influence of caffeine and terrible ideas, raised my hand.I've long been inspired by this lovely bog dress: the original was woven in a contiguous tube and fastened at the shoulder by brooches. it looks a lot like a roman chiton, which frequently had decorative bands at both the folded hem and the bottom hem. I had the thought of adding wide embroidered bands at the hems. The queen's favor is based on a pictish rune stone, so there was a ready source of designs. I decided I wanted to showcase the wide variety of pictish beasties on the rune stones in the pattern, a wide trim at the bottom hem, and a narrower band across the breast featuring the princess's two tailed mermaids at the center front and back, and some celtic knotwork roses symbolizing her status as a lady of the rose.

First I had to choose a fabric and techniques. The original gown is in wool, and I wanted to use wool for this one, but light enough that she could wear it in the summer. I also wanted to use purple, which was a color reserved for royalty in ancient Ireland (according to ye ancient irish bard of incredible helpfulness, Aife, who was my adviser in all matters ancient ireland for this entire project, and saved me innumerable hours of research and dead ends. ) I decided on a summer weight, almost sheer wool and that I could dye to get the correct color. Although Lichen dying has been a long time interest of mine, a little research showed it to be problematic. Aside from the fact that lichen dyes are notoriously difficult to get light fast, there is the problem with sustainability. It's generally recommended that lichen dying only be used for small projects or samples, because harvesting destroys the plant, which does not regenerate. I decided that I could use acid dyes to achieve the color I wanted. The fabric, a white wool crepe, was donated by a very generous patron.

I decided to use mounted bands of embroidery, worked in wool on lightweight linen, both to make working the embroidery more portable and convenient, and to hide the messy backside of the work. The additional benefit is that HRH can transfer the bands to another garment if she should so wish.

Rune stones of all sorts have been a long time fascination of mine, so it was fun to have an excuse to look at a lot of them. I spent a very enjoyable afternoon stalking museum collections and saving images, I came up with a large number of different wonderful patterns and beasts. In fact the most difficult part was deciding which ones to leave off.

I drew my chosen desings on a long strip of butchers paper, 7.5 inches wide, by 96 inches long. I centered a rose with a celtic knot detail at the four quarters, and bracketed it with sea serpents front and back. Then positioned a pair of animals in each space. Some of the animals had to be slightly altered to fit the space, particularly the gryphon: who was squashed into a long narrow border space, and the merhorses: which were entwined vertically, not horizontally. I then drew on the back of the paper with a heat transfer marker. This was my first time using this method of transfer, and I'm very pleased with it for this kind of work, although the line is fairly fat, so it's not a one size fits all solution. Working with it is a lot like working with the metallic paint pens, where you shake to mix the ink, then depress the tip to start the flow. I found it had the same weakness as those pens, after a while of use the tip starts to dry up, or the ink to separate again, so you have to occasionally shake the pen up and re-depress the tip to keep the ink flowing well. After i did the first transfer, I could tell where the pen had gotten a little dry because it didn't transfer as darkly. I ended up gong over the lighter areas with my fine tip sharpie to get clearer lines. The second transfer I worked I watched to be sure the ink was going on thickly enough, and shook/re inked the tip as necessary, and got very even dark transfer lines.

I had ordered silver thread for the detail work, and appleton's crewel wool for the bodies. I've used appleton's before and it's my favorite. very fine, very uniform. I worked the outlines in stem stitch in charcoal, which i thought would give a slightly softer look than true black, then mounted the embroidery in a hoop and started the long process of the bayuex stitch filling.

I started with the roses which I did not do in bayuex totally. I worked the edges in stem, as seen in small areas on the bayeux tapestry. Then filled the petals interior with satin stitch, and held it down with the silver metallic couched down with silk thread. I'm really liking working with better metallic thread. it's still a giant pain, but it's considerably less painful than the cheap stuff. This from Kyoto Embroidery is reasonably priced, and comes from japan in a lot of weights and colors.

I started with the roses which I did not do in bayuex totally. I worked the edges in stem, as seen in small areas on the bayeux tapestry. Then filled the petals interior with satin stitch, and held it down with the silver metallic couched down with silk thread. I'm really liking working with better metallic thread. it's still a giant pain, but it's considerably less painful than the cheap stuff. This from Kyoto Embroidery is reasonably priced, and comes from japan in a lot of weights and colors.

Then I did the bracketing sea serpents, working the bellies in bayeux, and then filling the backs with satin and couching it down with a lattice.

Then it was on to the rest of the animals. First filling in the accent or shading areas, very small or wiggly areas with stem stitch, and blocks with more bayux (antlers are stem. colored areas are bayeux. the shading on the legs/belly was achieved by alternating threads of black and brown before couching over it with brown.

Then it was on to the rest of the animals. First filling in the accent or shading areas, very small or wiggly areas with stem stitch, and blocks with more bayux (antlers are stem. colored areas are bayeux. the shading on the legs/belly was achieved by alternating threads of black and brown before couching over it with brown.

Then filling in the background color

Then repeat with the next animal.....

Then repeat with the next animal.....

I had lots of help from his royal puttyness, in a supervisory and thread warming role......

|

| Finally finished! |

With the hem done, I scoured the white wool crepe with dharma textile detergent (a synthrapol alternative) and got out my patent pending dying rig for large batches: a large steel garbage can, that I put on my big outdoor propane burner. I have an old shovel handle that's a perfect stirring device. I got lucky with this dye job: I was rushing, trying to watch the kids and work, and had a head cold when I did this. I made a paste with the dye powder and water, stirred in more water slowly, but neglected to strain this mixture into the dye pot. Just, dumped it in then added presoaked fabric. When I stirred? little clumps of dye all over the fabric. It hadn't all dissolved. I spent the next half an hour elbow deep in the scalding water, scrubbing little spots of undisolved dye so they'd dissolve in the hot water. Between that, and the glauber's salt I added to keep it level, amazingly the dye job is perfectly even. However, not at ALL the color I was expecting out of "purple haze." thankfully, while it's not Lichen purple, it is (as pointed out to me by BestLaurel when I panic messaged her) shoo in for tyrean purple, and very pretty. I called it a happy accident and went with it.

With the hem done, I scoured the white wool crepe with dharma textile detergent (a synthrapol alternative) and got out my patent pending dying rig for large batches: a large steel garbage can, that I put on my big outdoor propane burner. I have an old shovel handle that's a perfect stirring device. I got lucky with this dye job: I was rushing, trying to watch the kids and work, and had a head cold when I did this. I made a paste with the dye powder and water, stirred in more water slowly, but neglected to strain this mixture into the dye pot. Just, dumped it in then added presoaked fabric. When I stirred? little clumps of dye all over the fabric. It hadn't all dissolved. I spent the next half an hour elbow deep in the scalding water, scrubbing little spots of undisolved dye so they'd dissolve in the hot water. Between that, and the glauber's salt I added to keep it level, amazingly the dye job is perfectly even. However, not at ALL the color I was expecting out of "purple haze." thankfully, while it's not Lichen purple, it is (as pointed out to me by BestLaurel when I panic messaged her) shoo in for tyrean purple, and very pretty. I called it a happy accident and went with it. thankfully the bog dress is just a tube, so it's a matter of sewing rectangles together with a reversible seam (in this case flat felled). I felt rather badly for mounting this much work on a machine sewn dress, but at this point I was rapidly approaching deadline and slightly panicked, so I swallowed my scruples and moved on to mounting the hem. FirstI pinned the SNOT out of it, and machine sewed it to the bottom edge of the dress. Because my slate frame was occupied I did this on a round frame, and it DID allow the fabric to pucker a little. Lesson learned, next time just suck it up and take the other project off the slate frame (or you know, buy a second slate frame??) You just don't get as even of tension on larger projects on the circular cross stitch frames, and they don't grip evenly if you're expecting them to grip over bumpy areas (like previously embroidered figures).

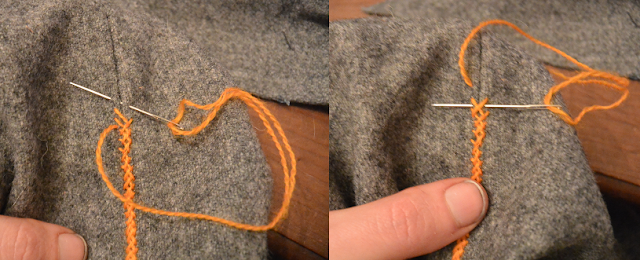

thankfully the bog dress is just a tube, so it's a matter of sewing rectangles together with a reversible seam (in this case flat felled). I felt rather badly for mounting this much work on a machine sewn dress, but at this point I was rapidly approaching deadline and slightly panicked, so I swallowed my scruples and moved on to mounting the hem. FirstI pinned the SNOT out of it, and machine sewed it to the bottom edge of the dress. Because my slate frame was occupied I did this on a round frame, and it DID allow the fabric to pucker a little. Lesson learned, next time just suck it up and take the other project off the slate frame (or you know, buy a second slate frame??) You just don't get as even of tension on larger projects on the circular cross stitch frames, and they don't grip evenly if you're expecting them to grip over bumpy areas (like previously embroidered figures).then flip it up, and more pinning! Crepe is stupidly stretchy, and doesn't want to stay put)

I worked over the edges with couched silver thread. This thread comes in skeins, and I've found that toilet paper rolls, or better yet, sections of stiffer paper towel tubes, work great to wind them onto. It's big enough in diameter that the thread doesn't get kinks, and you can make a slit in the end to catch the thread, because metallic is SUPER springing and will basically leap off the roll. then I bound the top edge with a strip of blue, and sewed the edge of that down with couched silver. At this point I called it done enough, because I wasn't sure if I started the mermaid on the top, I would be able to finish it before the event.

|

| Front, the mermaid will be centered on the fold down portion, with a pair of crescent moon and V rods. |

|

| Side |

|

| Back |

I was really pleased to be able to do this for the guild and for the queen! She really liked it as it was, but I did end up bringing it home to finish putting the mermaid on the front.

|

| The deputy guildmistress and I present the gift in court. Photo Credit Cataline la Broderesse |

|

| The best thing is having something you made make someone else happy! (Photo credit Cataline La Broderesse) |